August 30, 2021

Raute develops AI tools in InDEx program to develop more energy-efficient plywood mills

Raute, a global supplier of plywood and LVL production technologies, is developing AI tools to provide its customers with more energy-efficient, higher yield and less waste producing solutions. The quality of plywood can be improved if individual veneer sheets can be traced from the beginning to the end of the production process. The journey of veneer sheets from log to plywood requires many steps where it is very impossible to use stickers or other marking means as tags. Instead, identification by means of cameras and artificial intelligence has been developed, which is also cheaper in terms of operating costs than, for example, the use of RFID tags.

Raute has developed an AI algorithm for process monitoring and control in DIMECC’s InDEx (Industrial Data Excellence) program, which focuses on data sharing and utilization in the manufacturing industry.

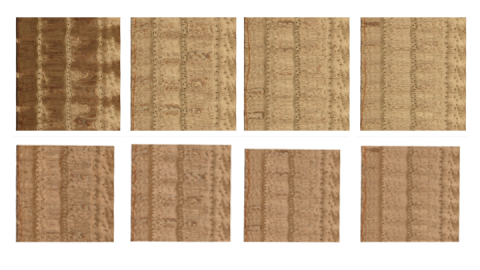

The research concentrated on how to identify the wet veneers on the top row from the same veneers after the drying process on the bottom row. Image: Raute Veneer21 dataset

Saving energy and material resources

The veneer sheets photographed at the beginning and end of the production process can be identified using an AI algorithm, which enables obtaining information about the changes caused by the process in an individual veneer sheet. This information can be used to adjust the machines to achieve the optimum result.

“Raute’s goal is to significantly reduce material waste. By developing these solutions, we are able to offer our customers entities that save energy and material,” says technology manager Jyrki Pesonen of Raute.

In the method developed by Raute in cooperation with the Tampere University, the algorithm identifies veneer sheets with an accuracy of 98.5 percent.

The InDEx program is digitizing industry

DIMECC’s InDEx (Industrial Data Excellence) program focuses on digitizing Finnish industry and building a data community and a common data platform. Konecranes, Danfoss, Elekmerk, Fastems, HT Laser, PrimaPower, Raute, SSAB and TietoEVRY participate in the program. Academic partners are Aalto University, Tampere University, University of Turku, University of Helsinki, University of Jyväskylä and VTT. The InDEx program is co-financed by Business Finland and the participating companies. It is an Intelligent Industry ecosystem development project.