June 16, 2022

InDEx program researched how machines from different manufacturers share data seamlessly.

InDEx program researched how machines from different manufacturers share data seamlessly.

Konecranes, Danfoss and Fastems are interested in utilizing their existing data sets to create new business. The InDEx program, led by DIMECC, took steps towards new intelligent solutions by building a prototype smart factory where data sharing and common interfaces could be tested. In the experiment, all three industrial companies integrated their operations on the same platform.

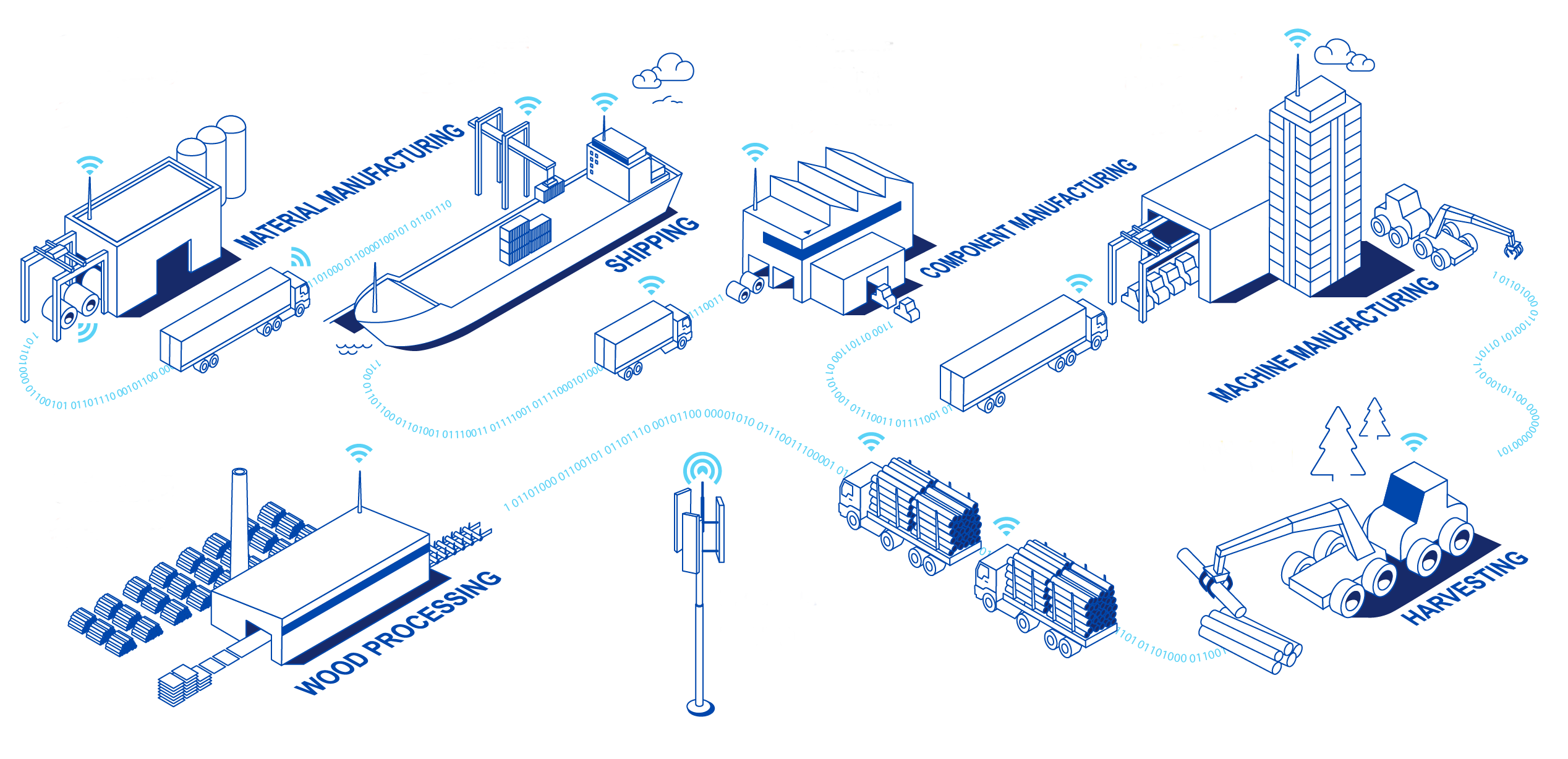

The prerequisite for intelligent factory production solutions is that the machines are connected to the company’s systems and to machines in the same factory environment. The basic requirement for sharing data and information between machines is a common and easy-to-implement interface for data transfer.

Konecranes built a prototype of an intelligent factory in which the control system was distributed throughout the plant. Various IoT devices transmitted information to the crane, and based on the information received, the crane was able to perform material transfer tasks automatically as needed. The European IDS (International Data Spaces) platform, whose liaison organization in Finland is VTT, was utilized in the transmission and processing of data generated by Fastems and Danfoss equipment. The intelligent factory was the most extensive test of the IDS platform in Finland and Europe.

The implementation of the smart factory model has proved useful.

“Smart factory cells with smart crane operations have great potential to boost productivity going forward”, Konecranes Research Engineer Juhani Kerovuori says.

The model also prepares for the shift, where factories transform from hierarchical control models to more decentralized models with a greater role for cloud-based analytics and optimization.

The InDEx project digitizes industry

DIMECC’s InDEx (Industrial Data Excellence) project focuses on digitizing Finnish industry and building a data community and a common data platform. Konecranes, Danfoss, Elekmerk, Fastems, HT Laser, PrimaPower, Raute, SSAB and TietoEVRY participate in the program. Academic partners are Aalto University, Tampere University, University of Turku, University of Helsinki, University of Jyväskylä and VTT. The InDEx project is co-financed by Business Finland and the participating companies. It is a Finnish Advanced Manufacturing Network (FAMN) development project.

Link to InDEx final report

Link to InDEx program page