September 30, 2014

A finite element model for simulating the SPS process (temperature gradients, distribution of electric current) was developed to enhance process control and facilitate design of complex SPS geometries.

A finite element model for simulating the SPS process (temperature gradients, distribution of electric current) was developed to enhance process control and facilitate design of complex SPS geometries.

RESULT

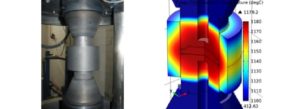

Spark Plasma Sintering (SPS) is an advanced sintering technique that uses pulsating DC and uniaxial force to consolidate particulate materials and join layered structures. In this project, a finite element model for simulating temperature and electric current distributions during SPS process was built using Comsol Multiphysics® software. The model is capable of simulating temperatures accurately (± 5 °C) up to 1100–1200 °C within the compact and the surrounding graphite mold. In addition to being suitable for various types of compact geometries and sintering cycles, the model includes an option to simulate densification as a function of sintering time and temperature.

MOTIVATION

SPS process is often characterized by rapid heating. Although the high heating rate promotes synthesis of nano-scale microstructures, it also makes the process susceptible to large temperature gradients. This results in a non-uniform microstructure. The problem is particularly severe with complex geometries and hybrid materials consisting of more than one material with significantly different physical properties from each other. In these cases modelling offers a much more efficient approach to process optimization than the conventional trial-and-error approach.

APPLICATIONS/

IMPACT

The constructed model is an efficient tool for process optimization and designing of complex SPS geometries. The model is readily applicable to different mould geometries, sintering cycles, and materials. It also includes an option to implement results from master sintering curve studies to simulate densification as a function of both sintering time and temperature. When combined with simulation of densification, it offers great potential for closing the gap between laboratory and full scale applications.

MAIN CONTACT

Juho Lotta, Aalto University

Erkin Cura, Aalto University

PROJECT PARTNERS